Products

LP filter tube

LP filter tube

LP filter tube is an inorganic material filter element with multilayer of filter structure, which consists of the supporting body and the filter membrane.

key word:

Category:

LP filter tube

Hotline:

- Description

- Operating Principle

- Performance feature

- Technical

- Application

-

- Commodity name: LP filter tube

- Commodity ID: 1072606813460516864

LP filter tube is an inorganic material filter element with multilayer of filter structure, which consists of the supporting body and the filter membrane.

LP filter tube is an inorganic material filter element with multilayer of filter structure, which consists of the supporting body and the filter membrane.

Supporting body

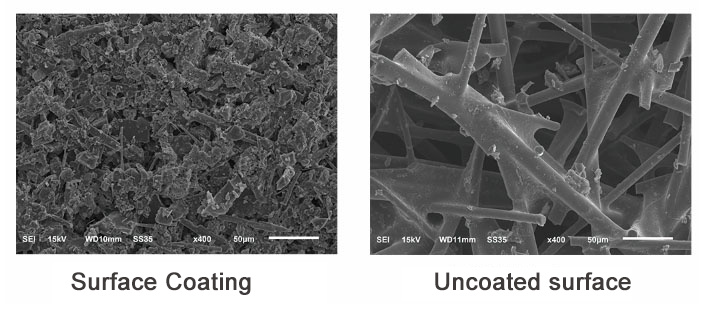

The supporting body consists of multiple layers, which are distributed in a ladder way from the inside out, to avoid individual powder from entering the filter body to cause clogging of the filter tube.Filter membrane

The filter membranes adopt different pores according to the distribution of powder particle size, to ensure the expected filter efficiency; besides, the filter membrane is hard, wear-resistant and bound with the supporting body very compactly.

Key words:

Key words:- LP filter tube

-

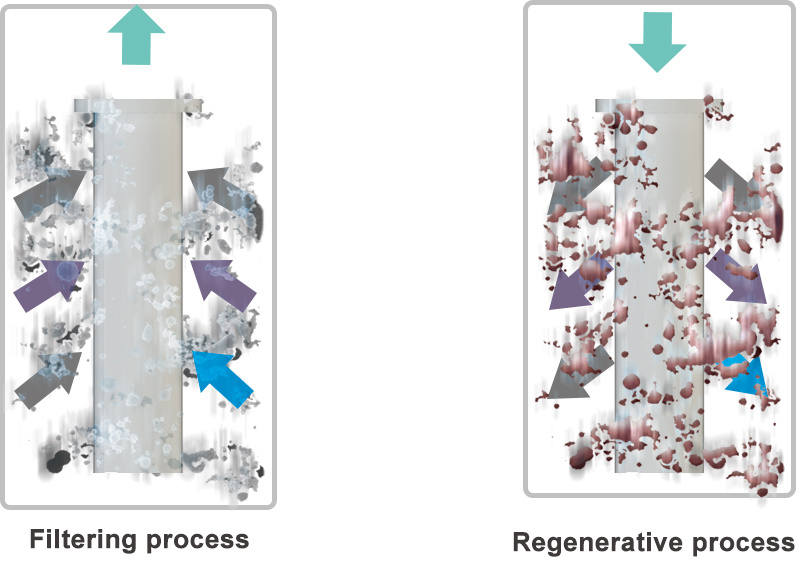

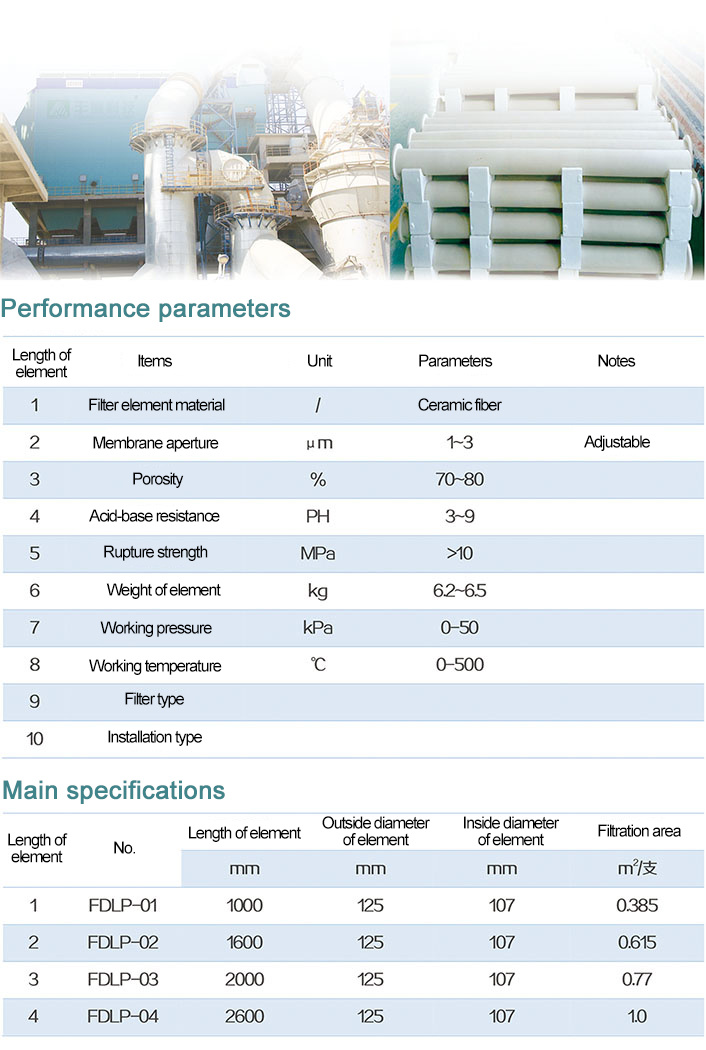

LP filter tubes are fixed to the ceiling of the filter device; and the ceiling plays a separation effect of the dust area and the clean area. The dust-containing gas enters the filter area, and passes through the filter tube from outside surface to the inner surface under the action of induced draft fan, and the dust particles are blocked the outer surface of the filter tube; the gas passes through the filter element, and then enters the gas purification room and the subsequent process.

With the accumulation of dust cakes, the internal and external pressure difference is becoming great; when the pressure drop reaches the designed value, the filter tube starts the backflush system. By using the reverse jet of the compressed air (or other gases), the instantaneous backward flow and pressure will remove the dust cakes adsorbed on the outer surface of the filter tube; when the dust cake is removed, it drops to the dust collector. After clearing the dust cake, the filter system starts a new cycle of dust removal.

-

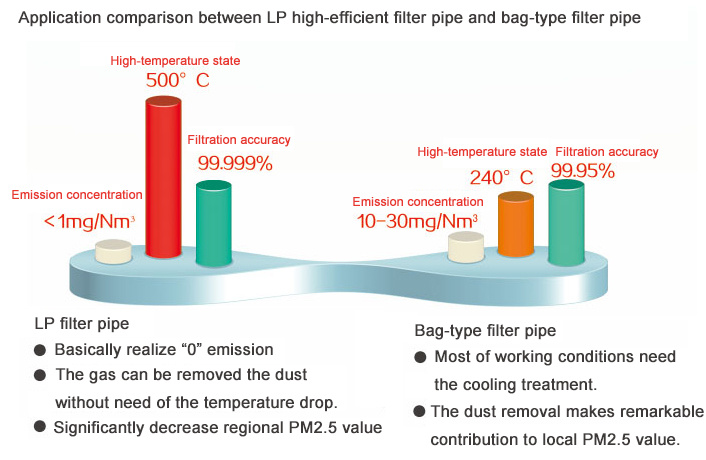

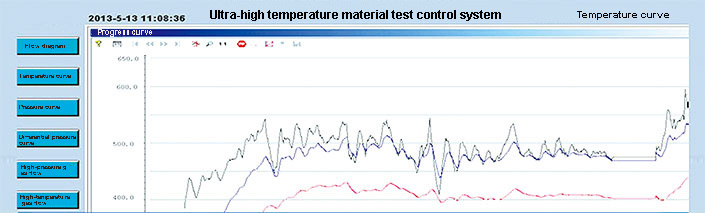

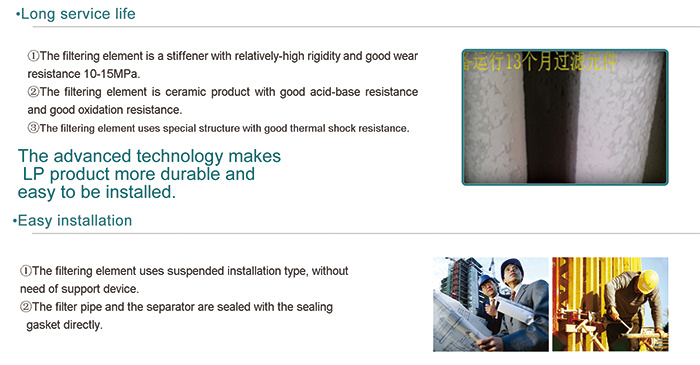

LP filter element is a filter material that can achieve the dust emission concentration less than 1mg/Nm³ at the high temperature 300-500 ℃ in the gas-solid separation equipment fields in the markets; and it has the features of good performance of high-temperature resistance, low resistance large flux, high filtration velocity and long service life.

The main material o LP filter element is Al2O3 fiber and binder, and its structure consists of the supporting body and filter membrane and it is made through high sintering, with the following features:

it can withstand higher temperatures, and its normal operating temperature may be 450 ℃-500℃, and its short-time operating temperature can be up to 550℃. Since the main material of LP filter tubes is Al2O3 fiber, the supporting body is a multi-pore body by overlapping of fibers with draw ratios, and the porosity is high; when heated, the internal stress stops extending due to the pores of the materials. The material will not be broken when heated with the low coefficient of linear expansion, and the multi-pore structure and membrane structure of the filter tube will not be damaged under the heat stress, showing excellent thermal shock resistance.

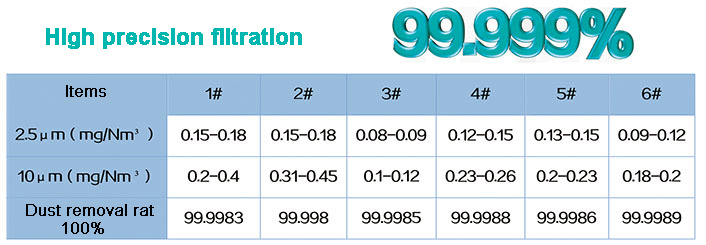

We have ever entrusted professional testing agencies to perform filter testing on the performance of the following common six groups o LP filter tubes; after filtered through LP filter tubes, the dust-containing dust emission concentration is less than 1mg/Nm³.

The surface of the LP filter tubes adopts inorganic film as the gas-solid separation layer; and particle size of the interred power particles can be controlled by the filter member pores; Appropriate filter members can be configured according to the filter requirements of different powder, and the median diameter o the filter pore can be less than 1µm, therefore, LP filter tube has high filter precision and the dust emission concentration can be less than 1mg/Nm³ (<1mg/Nm³).

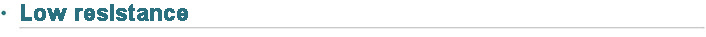

LP efficient filter tubes adopt the surface membrane filter way. In order to reduce the residues of extra-fine powder particles in the supporting body by passing through the filter membrane that may cause increased pressure as a result of clogging of filter tubes, the supporting body is composed of multiple layers; and the pore size becomes greater from outside to inside, forming a gradient pore structure. It can significantly reduce the filter pressure. At present, the clearance resistance of the products that have been put into production is less than 150Pa (1.0m / min).

LP efficient filter tubes adopt the surface membrane filter way. In order to reduce the residues of extra-fine powder particles in the supporting body by passing through the filter membrane that may cause increased pressure as a result of clogging of filter tubes, the supporting body is composed of multiple layers; and the pore size becomes greater from outside to inside, forming a gradient pore structure. It can significantly reduce the filter pressure. At present, the clearance resistance of the products that have been put into production is less than 150Pa (1.0m / min).LP filter tubes adopt the surface membrane filter way, with an asymmetric gradient pore structure. The porosity of the filter tube is up to 75%, the clearance resistance is around 150Pa (wind speed 1m / min); when operating, the filter pressure drop is close to or less than the conventional bags, and the resistance is lower under the same wind speed;

-

Other products

Product consultation