Products

High-temp Dedusting system

High-temp Dedusting system

Hefei Found Technology Co., Ltd. independently has developed a new high-temperature resistant material

key word:

Category:

High-temp Dedusting system

Hotline:

- Description

- Operating Principle

- Performance feature

- Technical

- Application

-

- Commodity name: High-temp Dedusting system

- Commodity ID: 1072604229534371840

Hefei Found Technology Co., Ltd. independently has developed a new high-temperature resistant material

Hefei Found Technology Co., Ltd. independently has developed a new high-temperature resistant material ---LP filter pipe, which can effectively separate the dust separation for less than 500℃ high-temperature flue gases, with the filter pipe resistance of less than 100Pa, dust emission concentration of less than 1mg/Nm³;

LP filter pipe can effectively reduce the total emission of the industrial dust up to 90%. Especially, a great number of particles with the diameter of less than 10√ are filtrated, thus reducing PM2.5 caused by the industrial dust sharply.Due to relatively-high flue gas temperature, some of technologies can’t use the bag-type dust remover directly, so the industrial flue gas must be cooled firstly:

1) Injecting cold air;

2) Spraying cold water;

3) Performing heat exchange (multi-pipe cooler, etc.)

In fact, the above methods need to invest a large amount of equipment, capital and manpower and to consume a large amount of energy.

Some of technologies, restricted by investment, site, process, etc., can’t perform the above methods, and existing dust-removing device can’t be applied. Direct flue gas emission will cause serious environmental pollution.Key words:- High-temp Dedusting system

-

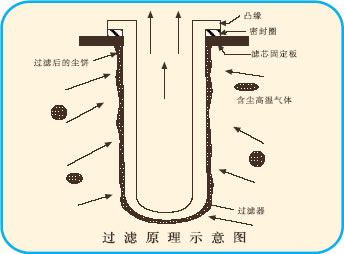

LP filter pipe is fixed onto the segregation board of the filtrating equipment to separate the dusty area from the clean area. The dusty high-temperature gas enters the dusty area, and passes the filter pipe from external surface to internal surface under the action of the induced draft fan. The dust particles are baffled by the external surface of the filter pipe, and clean gas enters the filter, and then is emitted into the clean gas chamber at the upper part of the filter. 。

-

1. Low pressure drop, low resistance;

2. Low emission concentration;

3. High service environment temperature;

4. Long service life;Low pressure drop, low resistance

1) Filtering element strength, high compressive strength, compressive strength of main body above 8MPa; 2) Filtering element low resistance, body resistance ≦100Pa (2.0m/min) filtering velocity of large bag-type dust remover 0.8-1.0m/min, no less than 1.2m/min. Because over-high air speed will make more fine powder through the filter bag, rise the emission concentration, add the equipment’s resistance and the system’s power consumption, and reduce the service life and enhance maintenance costs. The filtering velocity of LP filtration material is up to 3m/min (nearly 3 times that of the bag-type dust remover).Low emission concentration

1) The emission concentration of the LP filter pipe is up to 0.1mg/Nm3; the emission concentration of the system is less than 1mg/Nm3;

2) High filtration efficiency, low emission concentration, conventional flexible filter material. Even with the complex membrane, the dust content of the filtered flue gas is above 10mg/Nm3 at least;

3) The dust-removing system with the LP filter pipe can reduce the total emission of the existing dust-removing device up to 90%, which provides strong technical guarantee for solving the impact of industrial flue gas dust emission on PM2.5.

4) Under the condition of the flue gas treatment in the noble metal smelting, high filtration accuracy can recover more noble metal materials from the flue gas to enhance corporate benefit.High service environment temperature

1) Compared with conventional bag-type, LP filter pipe has the following characteristics. It can adapt to higher temperature. Influenced by the temperature tolerance, the working temperature of the existing bag-type dust remover is below 250℃. Our LP high-temperature filter pipe has normal working temperature up to 500℃, and maximum working temperature up to 550℃.

2) It can be used in multiple high-temperature flue gas conditions, without need of additional flue gas cooling devices such as cooler and atomizing humidifier, to perform high-temperature dust-removing filtration directly, which greatly streamlines the process, saves the investment and realizes energy conservation. Especially under the condition of the high-temperature gas, direct flue gas filtration can maintain high flue gas content to make full use of the heat energy.

Long service life

1) The filtering element is a ceramic product, with good acid-base resistance and good oxidation resistance;

2) The filtering element is a stiffener, with its surface having certain rigidity and good wear resistance;

3) The filtering element uses asymmetric gradient hole structure, which effectively prevents the filtration hole from being blocked, and prolongs the service life of the filter pipe;

4) Low equipment maintenance cost -

One: Performance:

1. Use the ambient temperature can reach 550 ℃;2. dust emission concentration ≦ 1 mg / Nm3;

3. life ≧ 3 years;

4. The running resistance ≦ 100 Pa

2: Technical parameters:

1. Length: 2.6 m;2. Diameter: 125 mm;

3. Weight: 6.5 kg;

4. filtration area: 1 m2;

5. Filtration rate: ≦ 3 m / min;

-

1. Flue gas dust removal prior to SCR denitration of coal-fired boiler;

2. Industrial gas purification;

3. The collection of the micro-fine noble metals in the flue gas

4. The emission of the ultra-purity dust in the high-temperature flue gas;

5. Flue gas treatment of converter or electric furnace;

6. The dust removal of the remaining air of the grate cooler at the cement kiln head;

7. Recovery or dust removal of the ultrafine powder;

8. Coal chemical industry;

9. Other industries: calcium carbide, oil shale, iron alloy, lignite refinery, biochemical engineering, waste incineration, glass-making, converter coal gas, etc.

Other products

Product consultation