Products

Desulfurization and denitrification system

Desulfurization and denitrification system

The diluted liquid ammonia (mass concentration20%~25%) or urea solution (mass concentration 30%~50%) is injected via the atomized spraying system

key word:

Category:

Desulfurization and denitrification system

Hotline:

- Description

- Operating Principle

- Performance feature

- Technical

- Application

-

- Commodity name: Desulfurization and denitrification system

- Commodity ID: 1072603880522141696

The diluted liquid ammonia (mass concentration20%~25%) or urea solution (mass concentration 30%~50%) is injected via the atomized spraying system

The diluted liquid ammonia (mass concentration20%~25%) or urea solution (mass concentration 30%~50%) is injected via the atomized spraying system into the proper temperature area of the decomposing furnace (850~1050℃) , and atomized ammonia and NOx (mixture of NO, NO2 , etc.) perform selective non-catalytic reduction reaction to convert NOx into the pollution-free N2. When the temperature in the reaction area is over-low, the reaction efficiency will be decreased; when the temperature in the reaction area is over-high, the ammonia will be oxidized into N2 and NO. After spraying ammonia, the chemical reactions inside the furnace include:

4NO+4NH3+O2→4N2+6H2O

6NO+4NH3→5N2+6H2O

6NO2+8NH3→7N2+12H2O

2NO2+4NH3 +O2→ 3N2+6H2OKey words:- Desulfurization and denitrification system

-

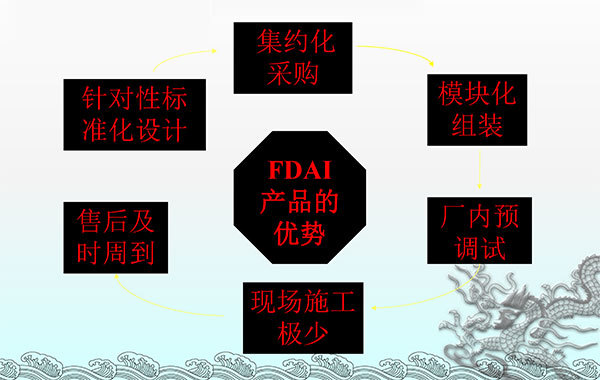

Advantages:

1. Its denitration efficiency (50-70%) basically meets the environmental requirement;

2. Simple device, low construction cost;

3. Without need of the catalyzer, low operation cost;

4. Easy to be implemented.

Defects:

1. Its denitration efficiency is relatively lower than SCR;

2. With high reaction temperature requirement, it needs to control the temperature in the reaction area accurately;

3. It needs relatively-high NH3/NOx value, because a part of NH3 is absorbed by the product.

-

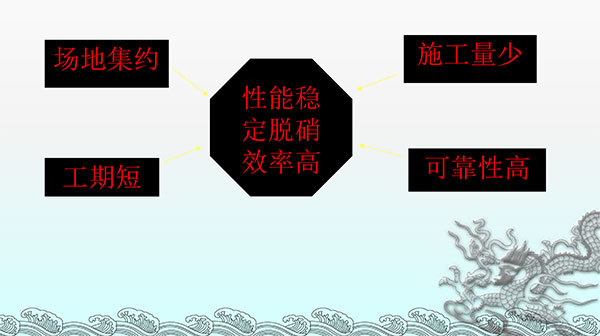

1.: High work efficiency, high flue gas purification degree.

1. It can reduce the content of the dust (including the particles below PM2.5) in the flue gases up to 5mg/m3 or below, SO2 30mg/m3 or below, and NOX 35mg/m3 or below. Moreover, it can remove some organic substances like dioxin and PAH and harmful substances like heavy metal.

Turning waste into wealth, with good economic benefit

2. It can convert some wastes in the flue gases, such as SO2 and NOX into chemical raw material, thus generating extremely-high economic benefit and recouping the capital outlay soon.2.: Small environmental costs

1. Compared with limestone or lime method, DDS dedusting agent, DDS desulfurizing agent and DDS denitrfying agent are recyclable. The technology with the limestone or lime as the desulfurizing agent will produce a large amount of calcium sulfate slag.

2. Compared with the technology with the ammonia or urea as desulfurizing or denitrfying agent, the synthetic process of the ammonia is a serious polluting process. The ammonia is emitted into the atmosphere to cause serious pollution, so traditional ammonia method for desulfurization and denitration is not a kind of environmental method, which increases pollution indirectly and produces serious secondary pollution indirectly.

3. Good solvent properties

The working solvent for the DDS technology has strong stability, strong oxidation resistance, slowness of deterioration, long failure time (In the 2-year fatigue test, few solvent failure has been founded), and small loss. It only needs to make up escaped, emitted, dropped and leaked solvent.

Big operating gas liquid ratio

4.DDS technology has big operating gas liquid ratio (500~1500) , small solvent circulating rate, low conveying energy consumption, low operating cost, short flow and simple operation.

Other products

Product consultation