Products

FDM pulse jet bag type dust collector

FDM pulse jet bag type dust collector

FDM series, pulse spray bag type received dust collector is Hefei Feng Technology Co., Ltd.

key word:

Category:

Bag-type dust colletion system

Hotline:

- Description

- Operating Principle

- Performance feature

- Technical

- Application

-

- Commodity name: FDM pulse jet bag type dust collector

- Commodity ID: 1072605108828262400

FDM series, pulse spray bag type received dust collector is Hefei Feng Technology Co., Ltd.

FDM series, pulse spray bag type received dust collector is Hefei Feng Technology Co., Ltd. in the digestive absorption of similar products at home and abroad the latest technology based on research and development of a new generation of efficient environmental protection bag type dust collector. The device using high-pressure or low-pressure large flow pulse valve and one by one the bag back blowing ash, dust removal efficiency up to 99.99%, its technical performance is the leading domestic level, the products are widely used in cement plant dust control and non - metallic mineral micro powder deep processing and power, chemical industry, metallurgy, iron and steel industry.

working principle

FDM type pulse jet bag filter adopts negative pressure operation, outside the filter form, high or low voltage pulse is applied to a large flow venturi induced anti-hair cleaning formula, both inertia and dust bag filter two functions.

(A) dust

Dusty gas into the chamber in advance dust, coarse dust particles fall into the hopper in the crash spoiler and under the action of gravity, inertia achieve dust; and a gas containing fine dust flows into the filter chamber equipped with bag by bag filtration clean gas through the net gas chamber, flues, discharged by the fan, filter bag outside the dust cleaning spray meridians fall into the hopper.

(B) cleaning

The device uses high or low voltage pulse is applied to a large flow venturi induced anti-hair cleaning formula, one by one through the bag and blowing big pulsing air flow, can be attached to the outside of the bag and shake off the dust, can be blown from the inside out transparent bag, high cleaning efficiency, product performance and stability.Features

1, using high-pressure or low pressure big flow pulse valve by one bag and anti-hair cleaning technology, high efficiency cleaning, dust removal efficiency of 99.99%.

2, dust control mode is divided into timing, resistance in two ways:

Timing control is to determine the parameters of the cleaning cycle time according to the device in actual operating conditions, designed to achieve the required resistance time, realize periodic automatic cleaning rotation, dumping of ash.

Fixed resistance control is based on pre-set cleaning dust collector resistance is controlled in turn, dumping of ash and other activities.

3, the cleaning operation is divided into two kinds of computer processing operation automatic control, manual:

The computer system is automatically controlled according to the timing control or setting parameters constant pressure controlled by a computer system for automatic cleaning control parameters can be revised by a computer.

Manual operation (typically used for debugging) is operating personnel cleaning operation according to the device parameters of the actual experience in normal operation conditions, time pressure or resistance values as shown in the instrument display.Key words:- FDM pulse jet bag

-

3.1 collecting mechanism

When the dusty gas from the mouth into the wind pipe or flange precipitator, guiding the duct, the duct cross-section to expand the wind decreases, part of the dust in the hopper wall of the settlement, fine dust flying into the bag along with the airflow chamber, and dispersed uniformly to each surface of the bag, the dust is retained in the outer bag, and the bag through the purge gas through the upper portion of the bag into the clean gas outlet casing, and finally discharged into the atmosphere through the exhaust fan outlet. Plot attached to the outside of the bag of dust, part by gravity fall into the hopper, and another part to remain in the outer surface of the bag, and gradually increased so that the resistance of the device. To ensure the resistance of not more than 1400Pa, at regular intervals or predetermined resistance requires cleaning once the dust deposited on the outside of the bag clean.

3.2 injection system works

Injection system works as follows: a termination compressed air impulse valve director, the other end of the injection tube. Pulse valve back pressure chamber connected to the exhaust valve, exhaust valve operation by computer control device operation, when the control device no signal output, the exhaust valve and plunger seal vent, pulse valve is in a closed state, when the control device when signaled exhaust valve pulse valve back pressure chamber and the atmosphere (relief) valve pulse instantly open. Fired into the air at great speed by the compressed air venturi tube through the main conduit through the injection tube orifice pulse valve, causing instantaneous positive pressure within the bag, to achieve pulse cleaning.

3.3 cleaning mechanism

In the net gas chamber, corresponding to the above each row of filter bags are equipped with a blow pipe, valve and compressed air pulse it in charge associated with a plurality of apertures on the injection pipe, each hole corresponds with a bag the center, the work can be set according to the nature of dust and gas in the case of computer control instrument cleaning cycle and injection time (can be adjusted at any time), when the dust collector work, the microcomputer controller will automatically send commands to control various in order to open the pulse valve, then the high-pressure air at great speed out of the nozzle, and attracted about five to seven times the amount of air ejected from the surrounding secondary gas by flare (venturi tube) mixed therewith, and then burst into the bag, like a top-down movement of the "bubble pulse" of the bag Guzhang deform, causing a small amplitude shock and vibration, while instant reverse airflow from the inside out, and will be deposited in the outside of the bag and shake off the dust to the hopper. -

FDM new pulse jet bag filter, is in the original MC-type pulse dust collector on the latest technology from home and abroad, combined with the actual situation of China's current pulse dust collector, bag filter developed from a new generation .

Precipitator high pressure (0.4 ~ 0.7MPa) one by one large flow stream pulse jet dust bag technology, with cleaning kinetic energy, high cleaning efficiency, compact structure, less maintenance and other characteristics, especially its re characteristic line of cleaning, dust collector allows continuous operation, to overcome the original mechanical rapping type dust collector cleaning downtime, equipment failure rate disadvantage, is an ideal environmentally friendly dust collection equipment.

Dust collector bag used in all film media, emission concentration is less than 20mg / Nm3, dust has collected 0.3 ~ 2μm are superior to any other type of precipitator dust collection efficiency.

The machine control system uses pulse jet control device, automatic control of the cleaning. -

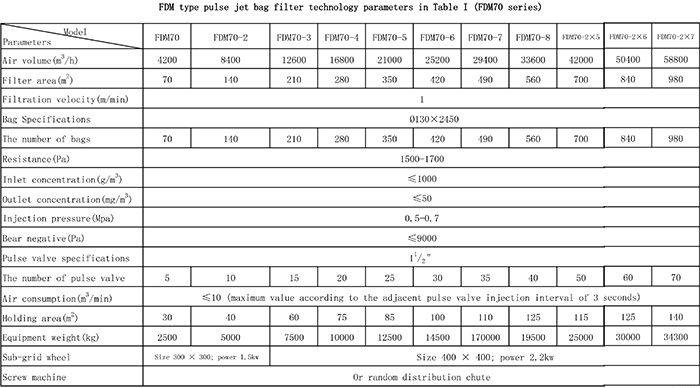

Note:

1 table air consumption of the plant gas supply situation when the maximum air consumption of the respective devices, when used alone, such as air compressors, gas consumption in the table should be enlarged to 1.5 times;

2, the weight of the equipment does not contain the table weight ladder, equipment leg mounting height any special requirements when ordering instructions required;

3, the above series of types of products only through systematic model, and the company can make a special selection of the specific circumstances of the user, which can be designed and manufactured to meet user requirements and models not included in the table of the same bag filter.

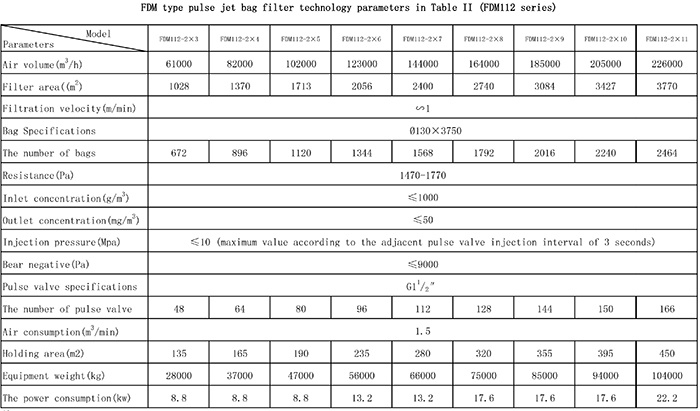

Note:

1 table air consumption of the plant gas supply situation when the maximum air consumption of the respective devices, when used alone, such as air compressors, gas consumption in the table should be enlarged to 1.5 times;

2, the weight of the equipment does not contain the table weight ladder, equipment leg mounting height any special requirements when ordering instructions required; ash optional equipment or spiral chute, thus reducing the number of sub-grid wheel;3, the above series of types of products only through systematic model, and the company can make a special selection of the specific circumstances of the user, which can be designed and manufactured to meet user requirements and models not included in the table of the same bag filter.

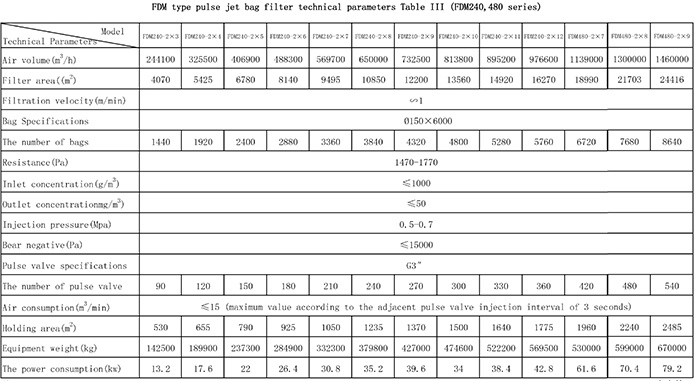

Note:

1 table air consumption of the plant gas supply situation when the maximum air consumption of the respective devices, when used alone, such as air compressors, gas consumption in the table should be enlarged to 1.5 times;

2, the weight of the equipment does not contain the table weight ladder, equipment leg mounting height any special requirements when ordering instructions required; ash optional equipment or spiral chute, thus reducing the number of sub-grid wheel;

3, the above series of types of products only through systematic model, and the company can make a special selection of the specific circumstances of the user, which can be designed and manufactured to meet user requirements and models not included in the table of the same bag filter.

Other products

Product consultation