Products

FDGL Pulse Bag Filter for Thermal Power Plant

FDGL Pulse Bag Filter for Thermal Power Plant

The series of FDGL bag filter for thermal power station is designed on basis of our long term experience on designing and developing furnace bag filter and the thermal power station’s special condition.

key word:

Category:

Bag-type dust colletion system

Hotline:

- Description

- Operating Principle

- Performance feature

- Technical

- Application

-

- Commodity name: FDGL Pulse Bag Filter for Thermal Power Plant

- Commodity ID: 1072606287184416768

The series of FDGL bag filter for thermal power station is designed on basis of our long term experience on designing and developing furnace bag filter and the thermal power station’s special condition.

The series of FDGL bag filter for thermal power station is designed on basis of our long term experience on designing and developing furnace bag filter and the thermal power station’s special condition. Compared with electric-static dust collector, FDGL bag filter has many advantages, such as: better efficiency, smaller in size, cheaper, low operating cost, offline dust cleaning,online or offline inspection, high automation, high temperature resistance filter media, etc. Take for the situations of heavy oil ignition, incomplete burned fuel,boiler tube explosion. The self inspection and control system are enhanced to ensure the equipment long term operation.

Key words:- FDGL bag filter

-

The working process of the bin type pump is divided into 4 phases:

1. Feeding phase

When the feeding valve is opened, the materials fall in the pump body freely. When the rising materials in the pump body touch the level gage, the level gage gives out the full-material signal, and the feeding system is closed automatically to complete the feeding process.

2. Fluidifying and pressing phase

The air inlet valve is opened automatically, the compressed air enters the bottom of the pump body, and is diffused through the fluidized bed. With the full fluidization of the material, the gas inside the pump rises.

3. Conveying phase

When the pressure inside the pump reaches a certain value, the pressure sensor gives out a signal, the discharge valve is opened automatically, the materials on the fluidized bed are conveyed, the materials inside the pump decrease gradually. In this process, the materials on the fluidized bed are fluidized and conveyed simultaneously.

4. Blowing phase

When the materials inside the pump are conveyed completely, and the pressure drops to pipeline resistance, The indicator light gives out a signal. The air continues to be taken in for a given time. Compress the air, and clean the pipeline. And then close the air inlet valve at a regular interval, close the discharge valve, open the feeding valve and complete one conveying cycle.

The above processes are performed automatically. -

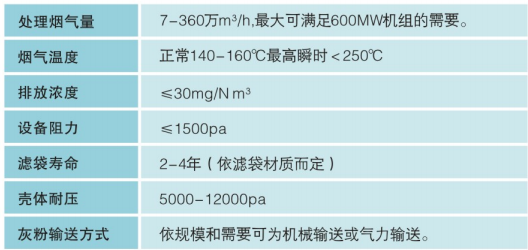

Process Air Volume: 7~3,600,000m3/h,satisfy the needs of 600MW motor

Dusty Gas Temperature: Normal140~160℃,transient temperature

Emission Concentration: ≤30mg/Nm3

Equipment Resistance: ≤1500pa

Filter Bag Service Life: 2~4years

Filter Body Pressure Load: 5000~12000Pa

Dust Convey Method: Mechanical or air-operated

-

Other products

Product consultation